Gone Sideways The Benefits Of Horizontal Boring Mills

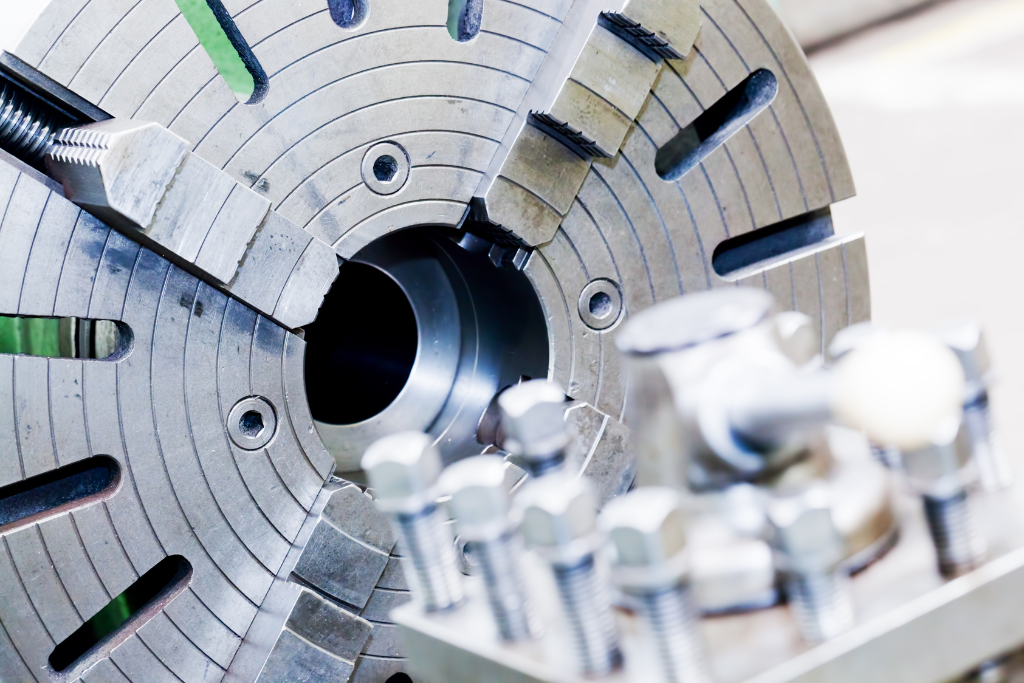

Boring is one of the most common operations, but sometimes regular lathes and mills can’t handle custom machined parts on the industrial level. Depending on the size of the part or tightness of the tolerances, a specialized machine may be just what you need.

The horizontal boring mill is unique in the way it gives you the ability to manufacture industrial parts that other machines can’t handle. There are several ways a horizontal boring mill can add value to your shop.

Make Big Parts

The number one benefit of the horizontal boring mill is its ability to manufacture large parts. Industries known for big parts like aviation, heavy construction, and oil-and-gas all depend on horizontal boring mills to make these parts as well as repair and maintain older machinery.

For example, in the aviation industry, boring mills are used heavily to repair landing gear and other flight essential parts that give aircraft longer life.

Parts With Less Chance For Error

Other machines like lathes and mills can rough and finish boring holes, but a horizontal boring mill offers more stability and power. An important concept to remember is overhang, or how far your tool is sticking out of its holder. The more overhang you have, the more likely you will have problems like tool deflection or missing your tolerance completely.

In most shops, the words “tool deflection” are spoken after a long string of cursing from a machinist when they find out the hole they just bored is larger at one end and smaller at the other. Tool deflection can cause other problems as well, but this is the most common.

Most horizontal boring mills have a spindle that extends out from the headstock for a longer reach. Tool deflection is reduced by the boring mill’s ability to hold the cutting tool close to the spindle without sacrificing that reach. This gives you the ability to cut deeper features without having to reposition the part. This also gives the cutting tool more strength when cutting pressure is applied so you can have the peace of mind that the cut will be straight and you won’t be pulling your hair out trying to fix it later.

Make Parts Faster

Horizontal boring mills are versatile but still specialized. They save you time by replacing the need to do your boring processes on other more general work machines. Horizontal machines cut faster, are more precise, and, in some instances, can make more than one cut at a time.

CNC Compatible

Most modern boring mills come equipped with CNC technology which further improves the versatility by allowing the machinist to pre-program each operation, saving time and eliminating the chance for error between steps. It also allows large batches of parts to be run one after another saving even more time.

For the machinist, CNC controls help make the machine feel more user-friendly and allows them to pay better attention to what the machine is doing the moment it’s doing it. Not needing to manually control the machine allows the machinist the awareness to potentially stop any major mistakes before they happen.

Type Of Horizontal Boring Mill You Are Looking For

There are three types of boring mills that give all the benefits that have been mentioned. The one you need will depend on the size and complexity of your operation.

Table-type boring mills are the most common type you will come across. Table-type boring mills have a rotating table that gives you the ability to use the spindle and table simultaneously. This makes it possible to machine complex multi-sided parts. This type of mill is also used for face milling operations.

Planer boring mills are similar to table-type boring mills but don’t have a rotating table. The table only moves perpendicularly to the spindle axis but, in return, provides excellent rigidity. Planer boring mills are best suited to highly critical operations.

Floor-type boring mills are recognizable by the large heavy mounting plates that sit on the floor. This type is for big parts that would be impractical to put on a planer or table-type boring mill.

Horizontal boring mills are exceptionally sturdy, durable, and reliable, especially if they are cared for properly. These machines can last for decades of consistent use, making them a good investment that retains their value.

A Great Addition To Your Shop

Horizontal boring mills are some of the more expensive machines available. Based on their size and technical requirements, some may shy away from this type of machine but think about the cost of a missed tolerance or a completely scraped part. Why take the risk if you can be sure? A high-end boring mill can get the job done that other machines simply can’t do.

Depending on the project you are working on, you can get your machine customized. From the amount of travel to the size of the table, you can talk to one of our team members here at Summit so we can get you exactly what you need.

.png)