How to Calculate ROI on Your CNC Machine Investment

Investing in a CNC machine is a significant decision for any manufacturing business. At DiPaolo Machine Tools, we understand that purchasing capital equipment like CNC machines requires careful consideration, especially when it comes to measuring ROI.

So how can you determine whether that investment is truly paying off? Let’s break it down.

1. Determine the Total Cost of Ownership

Start by identifying all costs associated with acquiring and operating the machine:

- Purchase price

- Installation and setup

- Training and onboarding

- Tooling and accessories

- Maintenance and service

- Energy consumption

- Software and licensing fees

The total cost of ownership gives you a true picture of your investment.

2. Calculate Financial Gains

CNC machines can generate value in several ways. You should quantify:

Increased Production Output

With automated processes, your shop can produce more parts in less time; leading to higher revenue.

Labour Cost Savings

CNC machines reduce manual labor and can run unattended for long hours, minimizing labour costs. Just as we look at the total cost of ownership, look at the total labour cost too. This could include, downtime due to staff shortages, recruitment and training costs, health and safety, employment related costs such as benefits, dues etc.

Reduced Scrap and Rework

CNC machines significantly reduce dimensional errors and inconsistencies, resulting in less material waste and fewer rejected parts. This precision minimizes the need for costly manual adjustments or secondary operations. Over time, the reduction in scrap not only saves on raw materials but also improves throughput, reduces labour hours spent on re-work, and enhances overall process reliability. Understanding the cumulative cost of scrap, both material and time, helps quantify how precision contributes directly to bottom-line savings.

New Business Opportunities

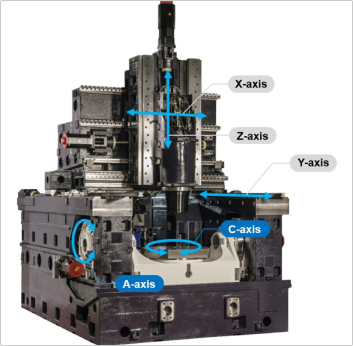

With advanced capabilities, you may be able to take on more complex or higher-paying jobs that were previously out of reach. Modern CNC machines often support tighter tolerances, faster cycle times, and multi-axis functionality, which can open doors to industries or customers with higher quality standards. Additionally, the ability to deliver precision parts consistently and efficiently can enhance your reputation, making your shop more attractive to new clients or larger contracts. Over time, this expanded capability can lead to increased market share and long-term revenue growth. With advanced capabilities, you may be able to take on more complex or higher-paying jobs.

3. Estimate Your Payback Period

The payback period helps you understand how long it will take for your investment in a new CNC machine to generate enough net benefits to cover its cost.

Here’s the simple formula:

Payback Period = Total Investment ÷ Annual Net Benefit

- Total Investment includes the purchase price, installation, tooling, training, and any upfront costs.

- Annual Net Benefit is the additional profit you gain each year from using the new machine — this might include:

- Reduced scrap and re-work

-

- Increased production capacity

-

- Lower labor costs

-

- New, higher-margin jobs

Example:

If the CNC machine and related costs total $250,000, and you estimate it will generate $100,000 in net benefits each year, the payback period would be:

$250,000 ÷ $100,000 = 2.5 years

That means your investment would pay for itself in two and a half years. After that, the machine continues to generate profit.

4. Analyze ROI Over Time

ROI improves as your machine continues to produce value. Once you pass the payback period, your profits are pure gain. Consider calculating:

- 3-year ROI

- 5-year ROI

- Lifetime ROI

This helps you compare the cost-effectiveness of different machines or justify reinvestment in new technology.

5. Consider Non-Financial Returns

While hard numbers are essential, don’t overlook non-financial benefits:

- Improved quality and consistency

- Increased competitiveness

- Increased health and safety

- Better labour utilization rates

- Faster lead times

- Enhanced reputation

These factors may not show up on your balance sheet, but they can significantly impact your long-term growth.

Let DiPaolo Help You Make the Right Investment

At DiPaolo Machine Tools, we’ve been helping manufacturers make smarter, more profitable decisions for decades. From evaluating your production needs to choosing the right CNC solution, we’re here to support your success—every step of the way.

Thinking about investing in a CNC machine? Contact us today for a personalized ROI analysis and equipment recommendation.